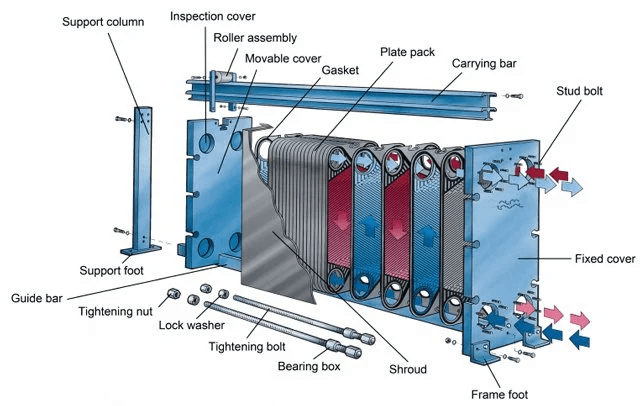

PHE’s (PLATE HEAT EXCHANGERS ) REFURBISHMENT

As well as being agents for leading Heat Exchanger companies, Sacome and Schmidt, Centri-Force is able to offer our customers a refurbishment service regardless of the type and manufacturer of each plate pack. Our workshop is fully equipped to clean, crack detect and re-gasket any type of Plate Heat Exchanger. Gasket Removal and Cleaning Old gaskets are removed and the plates are then put through a process of chemical cleaning which involves immersion of the plates in acid and alkali baths. The process is completed by high pressure rinsing in water. Crack Detection and Inspection Each plate is individually sprayed on one side with a dye penetrant and the opposite side sprayed with a developer. The plates are then inspected under Ultra Violet light to reveal any cracks or minute pin holes. Any faulty plates are removed, marked and returned to the client. Replacement plates are offered. Fitting New Gaskets New gaskets are applied to the plates using adhesives when necessary, unless clip type is used. The plates are re-configured into order, then jig-clamped and oven cured as necessary. The plates are finally inspected for bonding and fixing prior to despatch. Speed of Response We know that that for many customers, especially Ship Managers, speed of response and a reliable service is critical. Because we handle so many plate packs we have a team of engineers who are used to working under pressure and to deadlines. This means that we can offer the turnaround of refurbished plate packs that customers demand today.